Measurement guides are essential tools for ensuring accuracy and consistency in various fields. They provide detailed instructions and techniques for taking precise measurements, covering tools like calipers, tape measures, and digital devices. These guides are crucial for fashion, engineering, and healthcare, helping professionals achieve reliable results and maintain high standards in their work. By following measurement guides, individuals can minimize errors and ensure that their measurements are clear, consistent, and actionable.

1.1 Importance of Accurate Measurements

Accurate measurements are fundamental to ensuring quality, reliability, and safety across various industries. They prevent errors, reduce waste, and enhance precision in tasks like engineering, fashion, and healthcare. Clear and consistent measurements facilitate effective communication and problem-solving. For instance, in fashion, precise body measurements ensure a perfect fit, while in engineering, they guarantee structural integrity. In healthcare, accurate measurements are critical for diagnoses and treatments. Investing time in proper measurement practices leads to better outcomes, increased efficiency, and higher customer satisfaction. Whether for creating garments or manufacturing parts, accuracy is essential for achieving desired results and maintaining professional standards.

1.2 Overview of Measurement Tools and Techniques

Measurement tools and techniques vary widely, catering to different industries and needs. Common tools include calipers, micrometers, tape measures, and digital devices, each offering precision for specific tasks. Techniques range from manual measurements to advanced methods like 3D scanning and laser tools. Technical illustrations with arrows and guidelines are often used to clarify measurement processes. These tools and techniques ensure accuracy, consistency, and efficiency in fields such as fashion, engineering, and healthcare. Proper selection and use of measurement tools are critical for achieving reliable results and maintaining high standards in professional and technical applications.

Types of Measurements

Measurements are categorized into body, technical, and environmental types. Body measurements are crucial for fashion and sewing, while technical measurements are used in engineering. Environmental measurements monitor scientific data, ensuring accuracy across various fields.

2.1 Body Measurements for Fashion and Sewing

Accurate body measurements are vital for fashion and sewing to ensure garments fit perfectly. Key measurements include bust, waist, hips, inseam, and outseam. For tops, measure around the bust and from shoulder to waist. Pants require waist, hip, and inseam measurements. Use a flexible tape measure and keep it level. Technical illustrations with arrows can guide precise measurement points. Documenting whether waistbands are stretched or relaxed is crucial for patterns. Clear instructions help others understand the process. Videos and tutorials demonstrate techniques for accuracy. These measurements form the foundation for creating custom-fit clothing, making them essential for sewists and fashion professionals alike.

2.2 Technical Measurements for Engineering

Technical measurements in engineering require precision and accuracy to ensure the proper dimensions of components and systems. Tools like calipers, micrometers, and coordinate measurement machines (CMMs) are commonly used. Workshops, such as those organized by NPL, focus on measuring engineered parts with hand tools. The ASME B89.7.2 standard provides guidelines for dimensional measurement planning, emphasizing best practices for CMM use. These measurements are critical for problem-solving, data analysis, and manufacturing. Accurate technical measurements ensure reliability and consistency, making them indispensable in engineering and related fields. They form the backbone of quality control and innovation in industrial applications.

2.3 Environmental and Scientific Measurements

Environmental and scientific measurements are critical for understanding and monitoring natural systems. Tools like spectrometers and sensors are used to measure parameters such as air quality, water levels, and temperature. In scientific research, measurements often involve advanced techniques, including Fourier domain analysis and spatial domain conversions. These methods allow for precise data collection and analysis. Environmental measurements are essential for tracking climate change, ecosystem health, and pollution levels. Accurate scientific measurements enable researchers to draw reliable conclusions and inform policy decisions. They play a vital role in preserving our planet and advancing scientific knowledge across various disciplines.

Tools and Instruments for Measurement

Measurement tools range from basic hand tools like calipers and tape measures to advanced digital instruments. These devices ensure accuracy and precision in various fields, from engineering to fashion.

3.1 Calipers and Micrometers

Calipers and micrometers are precision tools for measuring dimensions accurately. Calipers are versatile, used for measuring diameters, depths, and distances between surfaces. Micrometers are ideal for smaller, intricate measurements, offering high precision. Both tools are essential in engineering and manufacturing for ensuring parts meet specifications. Proper calibration and technique are crucial to avoid errors. Regular maintenance ensures longevity and accuracy. These instruments are indispensable for achieving precise results in technical applications, making them cornerstone tools in many industries.

3.2 Tape Measures and Rulers

Tape measures and rulers are fundamental tools for measuring lengths and distances. Tape measures are flexible, making them ideal for body measurements in fashion and sewing, such as bust, waist, and hip circumference. Rulers provide straight-edge measurements, perfect for DIY projects and technical applications. Both tools are essential for ensuring accuracy in various tasks. When using tape measures, it’s important to keep the tape taut and aligned with the surface being measured. For rulers, clarity in markings and proper alignment are key to precise results. These tools are indispensable for everyday and professional use, offering reliability and simplicity in measurement tasks.

3.3 Digital Measurement Tools

Digital measurement tools offer advanced precision and efficiency for various applications. Laser measures provide quick and accurate distance calculations, while digital calipers are ideal for measuring small parts with high accuracy. These tools often feature data storage and Bluetooth connectivity, enabling easy transfer of measurements to devices for further analysis. Digital measuring tapes combine flexibility with electronic accuracy, making them versatile for both technical and everyday use. Their ability to convert units and store data enhances productivity, making them indispensable in engineering, construction, and scientific fields. Digital tools streamline workflows, ensuring reliable and efficient measurement processes.

Best Practices for Taking Measurements

Use calibrated tools, ensure clear documentation, and maintain consistency. Double-check measurements, use proper techniques, and verify results to ensure accuracy and reliability in all applications.

4.1 Ensuring Precision and Consistency

Ensuring precision and consistency in measurements requires using calibrated tools and following standardized techniques. Documenting each step clearly helps maintain accuracy and repeatability. For body measurements, consistent landmarks, like shoulder tips or hip bones, ensure reliability. In technical fields, using guidelines and technical illustrations with arrows can clarify measurement points. Regularly verifying tools and techniques minimizes errors. For example, stretching waistbands to a specific tension or using visual guides for armhole curves ensures consistency. Clear communication of methods and results is vital, especially in collaborative environments, to avoid misunderstandings and ensure everyone follows the same protocols.

4.2 Documenting Measurements Clearly

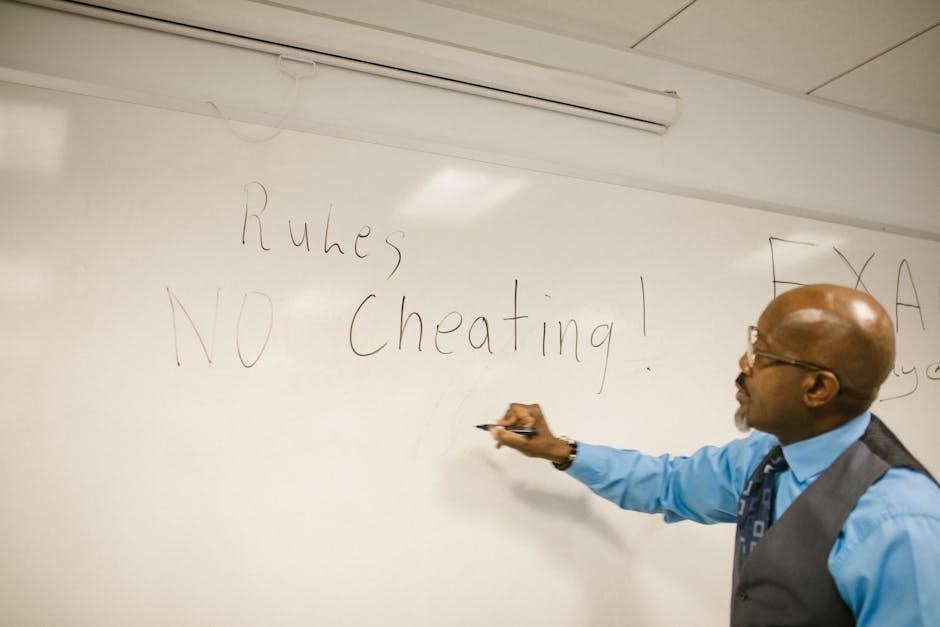

Documenting measurements clearly is crucial for accuracy and collaboration. Use photographs or technical flats with arrows to illustrate measurement points, ensuring clarity for others. Include details like stretched or relaxed states for elastic waistbands and specify landmarks for body measurements. Clear descriptions, such as “measure along the armhole seam from top to bottom,” prevent ambiguity. Organize data systematically, noting tools used and environmental conditions if relevant. This ensures consistency and reduces errors, especially in fields like fashion, engineering, and healthcare, where precise communication is vital for achieving accurate and reproducible results.

Understanding Measurement Uncertainty

Measurement uncertainty refers to the doubt associated with measurement results, crucial for reliable data analysis and problem-solving. It involves understanding statistical methods to calculate and report uncertainty accurately.

5.1 What is Measurement Uncertainty?

Measurement uncertainty is the doubt associated with the result of a measurement. It reflects the range of possible values within which the true value lies. Uncertainty arises from various sources, including instrument limitations, environmental factors, and human error. Understanding and quantifying uncertainty is crucial for reliable data analysis and decision-making. It ensures that measurements are reported with transparency and confidence, allowing for accurate assessments and comparisons. Properly addressing uncertainty enhances the credibility of results in fields like engineering, science, and healthcare, where precise and trustworthy data are essential for problem-solving and innovation.

5.2 Calculating and Reporting Uncertainty

Calculating measurement uncertainty involves statistical methods to quantify the range of possible values around a measured result. Techniques like maximum likelihood estimation (MLE) are often used to determine parameters from observed data. Reporting uncertainty requires clear documentation, stating the measured value along with its uncertainty range. Standards and guidelines, such as those from the National Institute of Standards and Technology (NIST), provide frameworks for accurate reporting. Properly calculated and reported uncertainty ensures transparency and credibility in scientific, engineering, and medical fields. It also helps in making informed decisions based on reliable data, fostering trust in the results and their applications.

Applications of Measurement Guides

Measurement guides are vital in fashion, engineering, and healthcare. They ensure accurate garment fitting, precise engineering specifications, and reliable medical assessments, enhancing quality and consistency across industries.

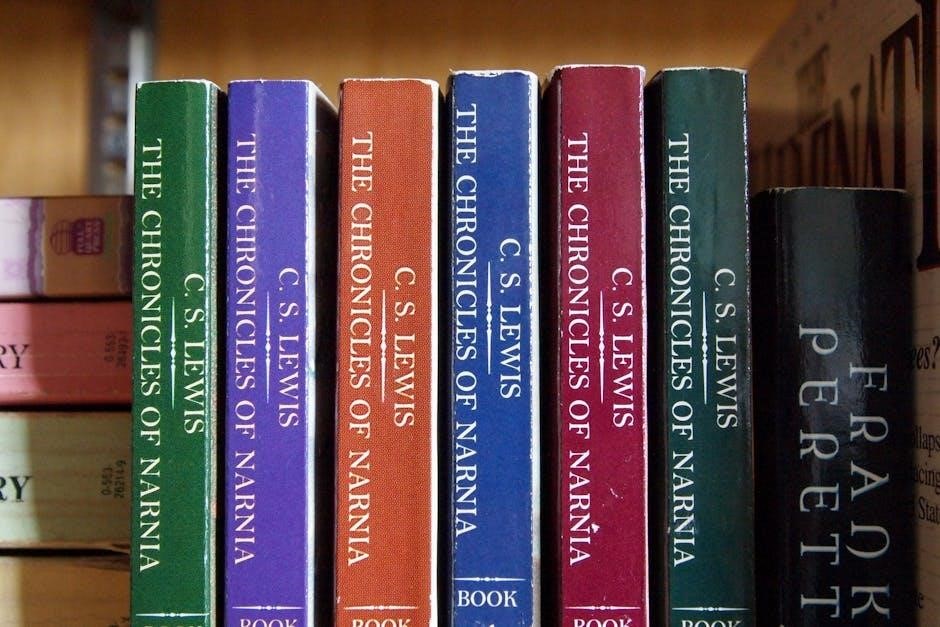

6.1 Fashion and Tailoring

In fashion and tailoring, measurement guides are indispensable for achieving precise fits. They detail how to measure body dimensions like bust, waist, and hips accurately. Technical illustrations and photographs are often used to clarify measurement points, ensuring consistency. For example, tutorials demonstrate how to measure armhole curves or elastic waistbands. These guides help create custom patterns and garments that fit perfectly, reducing the need for alterations. By following these standards, tailors and sewists can ensure their creations are both functional and flattering, catering to individual body types and styles effectively.

6.2 Engineering and Manufacturing

In engineering and manufacturing, measurement guides play a critical role in ensuring precision and quality. They outline best practices for using tools like calipers, micrometers, and CMMs to measure engineered parts accurately. Standards such as ASME B89.7.2 emphasize the importance of dimensional measurement planning. Workshops and resources, like those from NPL, provide hands-on training and tips for selecting the ideal measurement system; These guides help organizations maintain consistency, reduce errors, and comply with industry standards. By adhering to these protocols, engineers and manufacturers can achieve high levels of accuracy, ensuring the reliability and performance of their products.

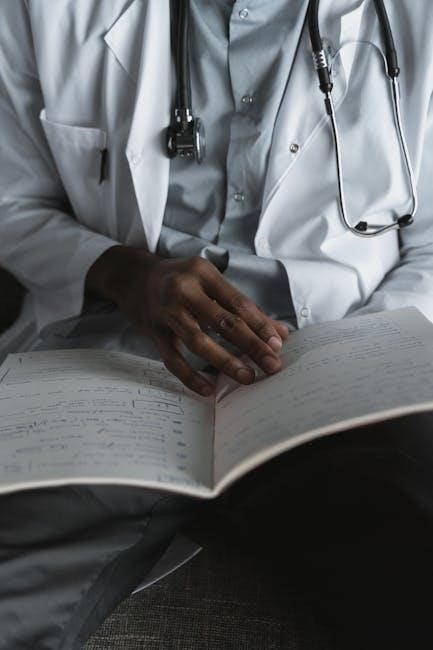

6.3 Healthcare and Medical Fields

In healthcare, measurement guides are vital for ensuring accurate assessments and treatments. They detail methods for using tools like digital scales, thermometers, and ECG machines. Reliable measurements are crucial for diagnosing conditions, monitoring progress, and administering medications. For instance, precise body measurements guide prosthetics and orthotics. Additionally, measurement guides help in calibrating medical equipment to maintain accuracy. In research, they ensure data integrity. Poor measurement practices can lead to misdiagnoses or ineffective treatments, emphasizing the need for adherence to established protocols. These guides are essential for maintaining patient safety and advancing medical science.

Advanced Measurement Techniques

Advanced techniques like laser measurement and 3D scanning offer high precision and efficiency. These tools enable detailed modeling and analysis, enhancing accuracy in complex applications across industries.

7.1 Using Laser Measurement Tools

Laser measurement tools offer unparalleled precision and efficiency in various industries. These devices use laser technology to measure distances, dimensions, and surfaces with high accuracy. Unlike traditional methods, lasers provide non-contact measurements, reducing the risk of damage to sensitive objects. They are widely used in engineering, construction, and quality control for tasks like aligning parts, inspecting surfaces, and calculating volumes. Advanced laser tools often integrate with software for real-time data analysis and 3D modeling. Their speed and reliability make them indispensable in modern manufacturing and scientific research, ensuring accurate and repeatable results in complex measurement scenarios.

7.2 3D Scanning and Modeling

3D scanning and modeling are advanced techniques that capture detailed digital representations of objects or environments. Using technologies like laser scanning or structured light, these tools create precise 3D models for analysis, design, and simulation. Widely applied in engineering, architecture, and healthcare, they enable accurate measurements of complex shapes and surfaces. The process involves capturing data points, which are then processed into a digital model. This technology enhances design accuracy, facilitates reverse engineering, and supports quality control. By integrating with CAD software, 3D scanning and modeling streamline workflows, improving productivity and innovation in various industries.

Resources and References

Explore tutorials, guides, and tools from organizations like NPL and National Instruments. These resources offer detailed measurement techniques, best practices, and advanced tools for precise data acquisition and analysis.

8.1 Recommended Measurement Guides and Tutorials

Discover a variety of resources, including tutorials from NPL and National Instruments, offering detailed measurement techniques. The iGUIDE system provides comprehensive guides for measuring properties. Videos and guides cover topics like body measurements for fashion, engineering tools, and scientific methods. Beginners can benefit from tutorials on uncertainty of measurement, while advanced users can explore 3D scanning and laser tools. These resources ensure accurate and efficient measurement practices across industries, helping professionals achieve precise results and maintain high standards in their work. They are essential for anyone looking to enhance their measurement skills and stay updated with the latest technologies.

8.2 Online Tools for Measurement Calculations

Utilize online tools like National Instruments’ DAQ systems and iGUIDE for precise measurement calculations. These platforms offer real-time data processing, 3D modeling, and advanced algorithms for complex measurements. Tools like NPL’s resources provide robust solutions for engineering and scientific applications. Online calculators for thickness, diameter, and shape measurements simplify tasks. Many tools are user-friendly, with cross-platform compatibility, ensuring accessibility for professionals and beginners alike. These resources enhance accuracy, efficiency, and innovation in measurement practices across industries, making them indispensable for modern applications.

Measurement guides are crucial for accuracy and consistency across industries. They provide essential tools and techniques, from traditional methods to advanced technologies like digital tools and 3D scanning. Embracing these resources ensures precision and efficiency, while staying updated on future trends like AI and IoT advancements in measurement technology.

9.1 Summary of Key Points

Measurement guides are vital for ensuring accuracy and consistency across various industries. They provide detailed instructions for using tools like calipers, tape measures, and digital devices. Key points include the importance of precise techniques, understanding measurement uncertainty, and documenting results clearly.

These guides are essential in fashion, engineering, and healthcare, offering methods to minimize errors and improve outcomes.

By following best practices and staying updated on advanced technologies, professionals can enhance their workflows and achieve reliable results.

Ultimately, measurement guides serve as foundational resources for anyone seeking to master the art of accurate measurement.

9.2 Future Trends in Measurement Technology

Advancements in measurement technology are expected to revolutionize industries through increased precision and automation. Laser-based tools and 3D scanning will become more prevalent, offering faster and more accurate data collection.

Integration of AI and machine learning will enhance analysis and reduce human error.

Portable and wireless devices will enable real-time measurements in diverse environments.

These innovations will streamline processes in engineering, healthcare, and fashion, ensuring higher efficiency and reliability.

As technology evolves, measurement guides will adapt, providing updated methods and tools to meet future demands.