The Franklin Electric Control Box Manual is a comprehensive guide for installing, troubleshooting, and maintaining control boxes, ensuring optimal performance and safety in submersible motor systems.

1.1 Overview of Franklin Electric Control Boxes

Franklin Electric control boxes are essential for submersible motor systems, designed to ensure reliable operation and safety. They feature heavy-duty terminals, quick-disconnect lids, and compatibility with 3-wire motors; These boxes meet rigorous industry standards, including LVD, EMC, and RoHS, ensuring durability and compliance. Their robust design and advanced engineering make them a trusted choice for various applications, from residential to industrial settings.

1.2 Importance of the Control Box Manual

The Franklin Electric Control Box Manual is crucial for proper installation, operation, and maintenance. It provides detailed wiring diagrams, troubleshooting guides, and safety precautions, ensuring optimal performance and longevity. The manual also includes technical specifications and compliance standards, helping users adhere to industry regulations. Accessible in PDF format, it serves as a one-stop resource for all control box needs, enhancing user confidence and system reliability.

Features and Benefits of Franklin Electric Control Boxes

Franklin Electric control boxes feature heavy-duty terminals and quick disconnects for easy troubleshooting. They are designed for compatibility with submersible motors, ensuring reliable performance and durability;

2.1 Key Features of Franklin Electric Control Boxes

Franklin Electric control boxes feature heavy-duty box-type terminals for reliable connections and quick disconnect (QD) designs for easy troubleshooting. They are engineered for compatibility with 3-wire submersible motors, ensuring seamless integration and optimal performance. These control boxes also meet rigorous safety and quality standards, including LVD, EMC, and RoHS compliance, making them durable and suitable for various applications.

2.2 Compatibility with Submersible Motors

Franklin Electric control boxes are specifically designed for compatibility with Franklin 3-wire, single-phase submersible motors, ranging from 1/3 to 1 hp. They ensure optimal performance and reliability when paired with these motors, adhering to nameplate ratings and technical specifications. This compatibility guarantees efficient operation and minimizes potential issues, making them a trusted choice for submersible motor systems.

2.3 Advantages of Using Franklin Electric Control Boxes

Franklin Electric control boxes offer robust performance, durability, and ease of use. They feature heavy-duty terminals and quick-disconnect designs for simplified troubleshooting. These boxes are engineered to withstand harsh environments and ensure reliable operation; Their compatibility with submersible motors and adherence to safety standards make them a preferred choice for efficient and secure electrical systems.

Technical Specifications and Ratings

Franklin Electric control boxes are designed for 3-wire submersible motors, featuring certifications like LVD and EMC, and offering enclosures suitable for both indoor and outdoor use.

3.1 Motor Ratings and Capacities

Franklin Electric control boxes are designed for 3-wire submersible motors, ranging from 1/3 to 1 hp, with compatible ratings up to 2 hp. They support motors with capacities from 0.25 to 3.7 kW, ensuring optimal performance. The control boxes are optimized for Franklin Electric motors, adhering to nameplate ratings for voltage, current, and power. This ensures safe and efficient operation across various applications.

3.2 Certifications and Compliance Standards

Franklin Electric control boxes meet rigorous international standards, including LVD (EN 61439-2:2011), EMC (EN 61439-2:2011), and RoHS (EN IEC 63000:2018). They also comply with EN 60529:1999/A2:2012 for environmental protection. These certifications ensure safety, reliability, and environmental compliance, making the control boxes suitable for global applications and adhering to regulatory requirements for submersible motor systems.

3.3 Enclosure Types and Environmental Suitability

Franklin Electric control boxes are available in various enclosure types, including Type 3R, suitable for both indoor and outdoor applications. They are designed to operate in temperatures as low as -10°C (14°F) and offer protection against dust and moisture, ensuring durability in harsh environments. This makes them ideal for diverse installations, from residential to industrial settings, while maintaining reliable performance and safety standards.

Installation and Wiring Guidelines

The manual provides step-by-step installation guides, wiring diagrams, and pre-installation checks to ensure safe and optimal setup of Franklin Electric control boxes for submersible motor systems.

4.1 Step-by-Step Installation Process

The manual outlines a detailed, step-by-step installation process for Franklin Electric control boxes, ensuring proper setup and functionality. It includes pre-installation checks, wiring connections, and mounting procedures. Heavy-duty box-type terminals accommodate up to AWG 2 wire, while Quick Disconnect (QD) boxes simplify troubleshooting by isolating control components. The guide emphasizes adherence to safety standards and compatibility with Franklin Electric submersible motors, ensuring reliable operation and system integrity;

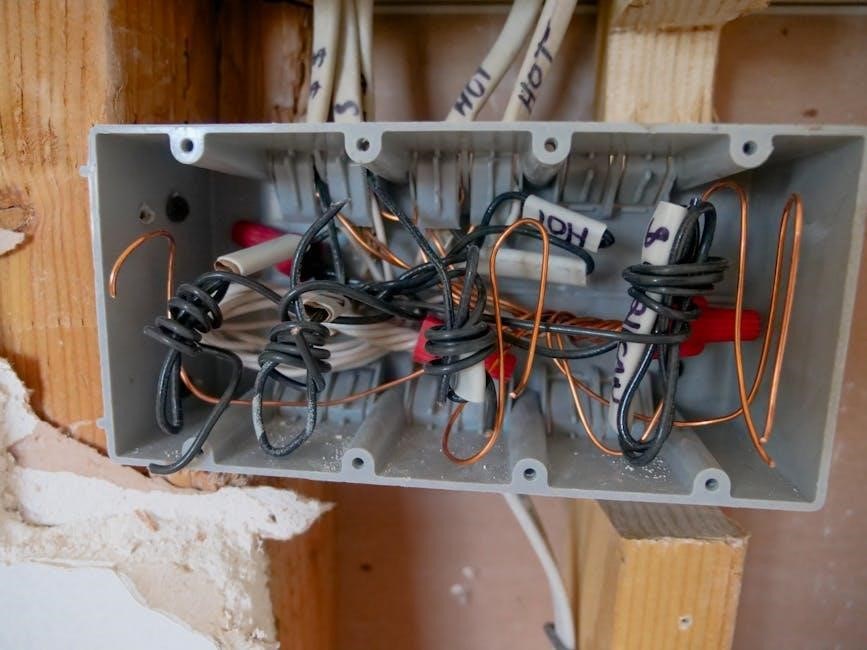

4.2 Wiring Diagrams and Schematics

The manual provides clear wiring diagrams and schematics to ensure proper connections for Franklin Electric control boxes. These visual guides detail terminal layouts, wire sizing, and circuit configurations, facilitating safe and accurate installations. Compatibility with 3-wire submersible motors is emphasized, along with adherence to safety and technical standards like LVD and EMC. The diagrams are essential for troubleshooting and maintaining system performance.

4.3 Pre-Installation Checks and Considerations

Before installing Franklin Electric control boxes, ensure compatibility with submersible motors and verify nameplate ratings. Check environmental suitability, including temperature ranges and enclosure types. Ensure all components meet technical standards like LVD and EMC. Properly assess wire sizing and system configuration to avoid electrical hazards. Always follow safety guidelines to prevent electric shock and ensure reliable operation.

Troubleshooting and Maintenance Tips

Identify common issues using diagnostic tools and follow maintenance procedures to ensure optimal performance. Regular checks and timely repairs extend the control box’s lifespan and reliability.

5.1 Common Issues and Solutions

Common issues include faulty relays, loose connections, and overheating. Solutions involve testing relays, tightening wires, and ensuring proper ventilation. Regular maintenance and inspections can prevent these problems. Always refer to the Franklin Electric AIM manual for detailed troubleshooting steps and guidelines to resolve issues effectively and safely.

5.2 Routine Maintenance Procedures

Regular maintenance ensures optimal performance and longevity. Check connections for tightness, inspect components for wear, and clean the control box to prevent dust buildup. Verify proper settings and update software if necessary. Refer to the Franklin Electric AIM manual for detailed procedures and schedules to maintain your control box efficiently and safely.

5.3 Diagnostic Tools and Techniques

Use multimeters to check voltage and resistance, ensuring proper electrical connections. Thermal imaging can detect overheating components. Refer to the Franklin Electric AIM manual for advanced diagnostic procedures. Utilize control box-specific software tools for real-time monitoring and fault detection. Regularly inspect relays, capacitors, and terminals for wear or damage. These techniques help identify issues early, preventing system downtime and ensuring reliable operation.

Safety Precautions and Best Practices

Always disconnect power before servicing. Wear protective gear to prevent electric shock. Follow manual guidelines for handling and storing components. Ensure proper grounding and ventilation.

6.1 Electrical Safety Guidelines

Always disconnect power before servicing. Use protective gear like gloves and goggles. Ensure proper grounding to prevent shock. Follow manual instructions for safe electrical connections. Avoid overloading circuits. Keep areas well-ventilated to prevent arc flash hazards. Never touch live components. Use insulated tools for added safety. Regularly inspect wires and connections for damage. Adhere to local electrical codes and standards for installation and maintenance.

6.2 Handling and Storage Recommendations

Handle control boxes with care to avoid physical damage. Store in a dry, cool environment away from direct sunlight. Keep units upright to prevent component displacement. Ensure storage areas are free from flammable materials. Use original packaging for transport to minimize risk of damage. Avoid exposure to extreme temperatures or humidity. Regularly inspect stored units for signs of wear or corrosion before installation or use.

6.3 Emergency Procedures and Shutdowns

In case of an emergency, immediately disconnect power to the control box. Use the emergency stop button if available. Allow the system to cool before restarting. Inspect for damage or faults. Follow proper shutdown procedures to prevent electrical shock or further damage. Always refer to the manual for specific emergency guidelines. Ensure safety protocols are strictly adhered to during any unexpected system failure or malfunction.

Compatibility with Franklin Electric Motors

Franklin Electric control boxes are specifically designed to work seamlessly with Franklin submersible motors, ensuring optimal performance and compatibility for various applications and power requirements.

7.1 Motor and Control Box Pairing Guide

Franklin Electric control boxes are designed to pair seamlessly with specific submersible motors, ensuring optimal performance. The guide provides detailed compatibility information, helping users match the correct control box with their motor based on horsepower, voltage, and application requirements. Proper pairing ensures efficient operation, safety, and longevity of the system. Always refer to the AIM manual for precise motor-control box configurations and technical specifications.

7.2 Ensuring Proper System Configuration

Proper system configuration is critical for optimal performance and safety. Always adhere to the control box’s nameplate ratings and technical specifications. Ensure compatibility with Franklin Electric motors by following the AIM manual’s guidelines. Verify wiring, voltage, and horsepower ratings match the motor and control box. Correct configuration prevents electrical issues, ensures efficiency, and extends system lifespan. Refer to the manual for detailed setup instructions and compliance with safety standards.

7.3 Upgrading or Replacing Motors and Control Boxes

Upgrading or replacing motors and control boxes requires careful planning. Always ensure the new components are compatible with existing systems. Refer to the Franklin Electric AIM manual for guidance on selecting the right upgrades. Follow installation instructions precisely to maintain system performance and safety. Proper replacement prevents electrical hazards and ensures optimal functionality. Regular updates help keep your system efficient and compliant with current standards.

Accessories and Additional Components

Franklin Electric offers a range of accessories, including spare parts and replacement kits, to enhance control box functionality and ensure system compatibility and longevity.

8.1 Optional Accessories for Enhanced Functionality

Franklin Electric offers optional accessories like Quick Disconnect boxes, which simplify troubleshooting by isolating control components. Additional components include variable speed drives, spare parts, and replacement kits, ensuring compatibility and system optimization. These accessories enhance control box performance, adaptability, and longevity, catering to specific application needs while maintaining compliance with industry standards and environmental requirements.

8.2 Spare Parts and Replacement Kits

Franklin Electric provides a range of spare parts and replacement kits to ensure seamless maintenance and repairs. These kits include components like terminals, relays, and capacitors, designed for easy replacement. Genuine parts guarantee compatibility and reliability, extending the control box’s lifespan. The manual offers detailed part numbers and diagrams, simplifying identification and ordering processes for optimal system performance and minimal downtime.

8.3 Compatibility with Variable Speed Drives

Franklin Electric control boxes are compatible with variable speed drives (VSDs), enhancing motor performance and efficiency. The manual provides guidelines for integrating VSDs, ensuring proper configuration and compatibility. This setup allows for precise speed control, reducing energy consumption and optimizing system operation. The integration supports advanced motor control, making it suitable for various applications requiring adjustable speed settings.

Parts Breakdown and Component Identification

Franklin Electric control boxes include detailed component breakdowns, helping users identify and understand each part’s function, ensuring proper maintenance and troubleshooting of the system effectively.

9.1 Detailed Component Overview

The Franklin Electric control box includes heavy-duty terminals, relays, capacitors, and disconnects. Each component is engineered for durability and efficiency, ensuring reliable operation. The Quick Disconnect (QD) feature simplifies troubleshooting by isolating control components. These parts are designed to work seamlessly with Franklin Electric submersible motors, providing a robust and maintenance-friendly system. Understanding each component’s role is crucial for optimal performance and longevity.

9.2 Understanding the Control Box Layout

The Franklin Electric control box features a logical layout with clearly labeled components, including terminals, relays, and capacitors. The Quick Disconnect (QD) design allows easy access for troubleshooting. Heavy-duty box-type terminals accommodate up to AWG 2 wires, ensuring secure connections. The layout is optimized for compatibility with Franklin Electric submersible motors, providing a user-friendly interface for installation, maintenance, and operation. This design enhances safety and efficiency in various applications.

9.3 Identifying and Replacing Faulty Components

Identifying faulty components in Franklin Electric control boxes involves checking relays, capacitors, and terminals for signs of wear or damage. Refer to the AIM manual for diagnostic guidance. Before replacing, ensure the system is powered off. Use genuine Franklin Electric spare parts for compatibility. Consult wiring diagrams for precise replacement procedures, and follow safety protocols to avoid electric shock or system damage during repairs.

Downloading and Accessing the Manual

The Franklin Electric control box manual is available in PDF format on the official Franklin Electric website, ensuring easy access for troubleshooting, installation, and maintenance guidance.

10.1 Official Sources for the Franklin Electric Control Box Manual

The Franklin Electric control box manual can be downloaded from the official Franklin Electric website, ensuring authenticity and reliability. Additional resources are available through authorized distributors and technical support platforms, providing easy access to the latest versions and updates. These sources guarantee accurate and comprehensive information for optimal system performance and safety.

10.2 PDF Format and Digital Accessibility

The Franklin Electric control box manual is available in PDF format, ensuring easy access and digital readability. This format allows users to search, zoom, and navigate content effortlessly. PDFs are compatible with most devices, making the manual accessible on computers, tablets, and smartphones. Franklin Electric also provides digital tools and resources to enhance accessibility and user experience, ensuring the manual is readily available for all users.

10.3 Updating to the Latest Version

Regularly updating to the latest version of the Franklin Electric control box manual ensures access to the most accurate and up-to-date information. Visit the official Franklin Electric website to download the newest PDF version. This ensures compatibility with the latest products and features. Users are encouraged to check for updates periodically to maintain optimal performance and compliance with current standards.

Franklin Electric AIM Manual Overview

The Franklin Electric AIM Manual is a comprehensive resource for submersible motor application, installation, and maintenance. It provides detailed guidance and troubleshooting tips, making it indispensable for professionals and technicians.

11.1 Purpose and Scope of the AIM Manual

The Franklin Electric AIM Manual serves as a vital resource for professionals, providing detailed guidance on submersible motor application, installation, and maintenance. It covers troubleshooting, best practices, and compliance standards, ensuring optimal system performance and safety. First introduced in the 1960s, the AIM Manual has become an indispensable tool for technicians and engineers working with Franklin Electric systems.

11.2 Key Sections and Information Included

The AIM Manual includes detailed sections on motor application, installation, and maintenance, along with troubleshooting guides and safety protocols. It provides technical specifications, wiring diagrams, and compliance standards. The manual also covers best practices for system configuration and diagnostic tools, ensuring comprehensive support for professionals working with Franklin Electric submersible systems. Regular updates reflect industry advancements and user feedback.

11.3 How to Use the AIM Manual Effectively

Refer to the AIM Manual for detailed application, installation, and maintenance procedures. Use the troubleshooting guides to diagnose and resolve common issues; Familiarize yourself with safety protocols to ensure secure operations. Access the manual digitally for convenience and regular updates. Leverage the comprehensive resource library for additional technical support and best practices, enhancing your proficiency with Franklin Electric systems.

The Franklin Electric Control Box Manual provides essential guidance for optimal system performance. Always follow safety protocols and refer to the AIM manual for additional support and troubleshooting.

12.1 Summary of Key Points

The Franklin Electric Control Box Manual offers detailed guidance on installation, troubleshooting, and maintenance; It emphasizes safety protocols, compatibility with submersible motors, and proper system configuration. The manual also highlights the importance of routine maintenance and diagnostic tools for optimal performance. By following the guidelines, users can ensure reliable operation and extend the lifespan of their control boxes and associated motors.

12.2 Final Tips for Optimal Use of Franklin Electric Control Boxes

Always adhere to the manual’s guidelines for installation and maintenance. Regularly inspect components and follow safety protocols to prevent electric shock. Ensure compatibility with Franklin Electric motors for seamless operation. Refer to the AIM manual for advanced troubleshooting. Schedule routine maintenance to prolong system lifespan. For complex issues, consult certified professionals to avoid damage and ensure optimal performance.