The FTC Game Manual is a comprehensive guide outlining rules, regulations, and season-specific details for the FIRST Tech Challenge. It ensures fair competition and clarifies expectations for teams.

1.1 Purpose and Structure of the Manual

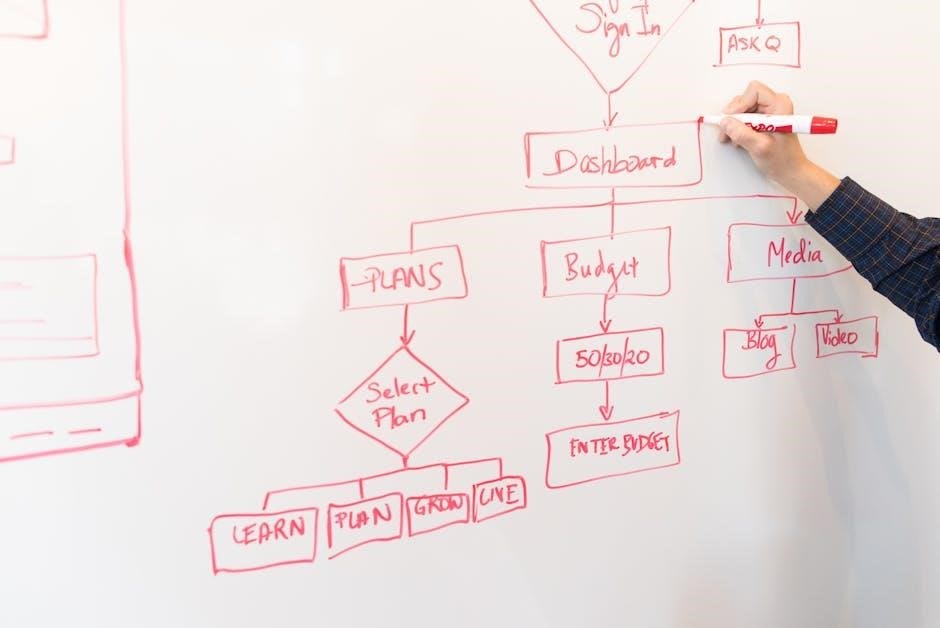

The FTC Game Manual serves as the official guide for each season, detailing rules, regulations, and guidelines for teams. Its purpose is to ensure fair competition and clarify expectations. Structured into sections, it covers game elements, robot specifications, scoring mechanisms, and competition formats. The manual is updated annually to reflect the current season’s theme and challenges. It provides detailed descriptions of field components, match dynamics, and judging criteria. Teams are encouraged to reference it regularly to stay informed and compliant. The manual is divided into logical chapters, making it easy to navigate and understand. It is the authoritative source for all FTC-related inquiries and is essential for success in the competition.

1.2 Importance of Adhering to the Manual

Adhering to the FTC Game Manual is crucial for ensuring fair competition and maintaining the integrity of the game. Teams must comply with all rules and regulations to avoid penalties or disqualification. The manual provides clear guidelines for robot design, game mechanics, and match procedures, ensuring consistency across all teams. Failure to follow the manual can result in penalties, affecting a team’s performance and ranking. It is the authoritative source for resolving disputes and clarifying ambiguities. Teams are expected to stay updated with the latest version, as changes can impact strategies and compliance. Adherence ensures a level playing field and fosters a competitive yet respectful environment.

Overview of the FTC Game

The FTC game, titled INTO THE DEEP for the 2024-2025 season, challenges teams to navigate an ocean-themed arena, emphasizing robot design, task execution, and strategic teamwork.

2.1 Game Title and Theme

The 2024-2025 FTC game, titled INTO THE DEEP, revolves around an ocean-themed challenge, emphasizing environmental conservation and underwater exploration. Teams design robots to perform tasks in an aquatic arena, promoting innovation and strategic thinking. The game’s theme encourages sustainable practices and continuous outreach, aligning with real-world environmental issues. Robots must navigate the field, interact with scoring elements, and complete missions inspired by oceanic conservation efforts. This season’s focus is on creativity, teamwork, and adaptability, as teams aim to address challenges like pollution and resource management through their robot’s capabilities. The manual provides detailed rules and guidelines for this immersive and educational competition.

2.2 Key Objectives and Challenges

The primary objective of the FTC game is for teams to design and operate robots that can perform specific tasks within the aquatic-themed arena. Challenges include navigating the field, manipulating scoring elements, and addressing environmental conservation themes. Teams must balance robot movement, element manipulation, and scorable tasks, often requiring innovative mechanisms. Sustainable continuous outreach is emphasized, with teams encouraged to focus on long-term impact over one-off events. The game demands strategic planning, precise engineering, and effective teamwork to overcome obstacles and achieve high scores. Adaptability and creativity are crucial as teams face dynamic challenges during matches and competitions.

Game Elements

The FTC game features a detailed field setup, scoring elements, and major mechanisms. These components address robot movement, element manipulation, and task performance, ensuring dynamic competition and innovation.

3.1 Field Setup and Components

The FTC game field is typically set up in a gymnasium or similar large space, featuring a 12×12-foot playing area. The field includes scoring zones, alliance stations, and various field elements such as bars, platforms, and interactive components. These elements are designed to challenge teams to navigate, manipulate, and score points effectively. The setup ensures a balanced and dynamic competition environment, with clear markings and zones to guide robot interactions. Major mechanisms, such as those addressing robot movement or element manipulation, are integral to the field design, ensuring teams can execute tasks efficiently. Understanding the field layout is crucial for strategic planning and successful gameplay.

3.2 Scoring Elements and Mechanisms

Scoring elements in FTC are designed to challenge teams to manipulate and interact with field components effectively. These elements, such as plastic bars or other scorable objects, are central to earning points. Robots must navigate the field to move, lift, or deposit these elements into designated zones. The scoring mechanisms are detailed in the manual, outlining how points are awarded based on placement, timing, and task completion. Teams must understand these mechanisms to maximize their scores. The design of scoring elements encourages creativity and precision in robot design, ensuring dynamic and competitive gameplay. Proper execution of these mechanisms is key to achieving success in matches.

Rules and Regulations

The FTC Game Manual outlines essential rules and regulations, including robot specifications, penalties, and disqualifications, ensuring fair and structured competition for all participating teams.

4.1 Robot Specifications and Restrictions

The FTC Game Manual details specific robot specifications and restrictions to ensure fairness and safety. Robots must adhere to size, weight, and material limits, with a maximum dimension of 18 inches in height, width, and length. Teams are restricted from using certain materials deemed unsafe or unfair. Additionally, robots must not exceed the defined weight limit to prevent damage to the field or other robots. The manual also outlines rules for major mechanisms, ensuring they address at least one game challenge without external assistance. Compliance with these specifications is crucial for eligibility and competition integrity, as non-compliant robots may face penalties or disqualification.

4.2 Game Mechanics and Interactions

The FTC Game Manual outlines the game mechanics and interactions that govern how robots engage with the field and scoring elements. Robots must manipulate scoring elements such as balls, blocks, or other objects to earn points. The manual specifies how these elements behave and how they can be interacted with during matches. Additionally, it details how robots can influence field components, such as levers, ramps, or gates, to achieve game objectives. Teams must ensure their robots’ actions align with these rules to avoid penalties. Proper understanding of these mechanics is crucial for designing effective strategies and ensuring compliance with competition standards.

4.3 Penalties and Disqualifications

The FTC Game Manual outlines specific penalties and disqualifications to maintain fair play and sportsmanship. Penalties are imposed for illegal actions, such as robot malfunctions or unsportsmanlike conduct, and may result in point deductions or temporary disqualifications. Disqualifications occur for severe or repeated violations, such as intentional interference with opponents or field components. Teams must adhere to these rules to avoid losing matches or being removed from the competition. The manual also specifies how penalties are tracked and applied during matches, ensuring consistency across all events. Understanding these guidelines is essential for teams to compete fairly and avoid unnecessary setbacks. Proper adherence ensures a level playing field for all participants.

Competition Format

The FTC competition format includes qualification matches, playoff rounds, and alliances. Teams compete in traditional events, often in gymnasiums, to advance through the tournament structure.

5.1 Types of Matches (Qualification, Playoff)

FTC competitions feature two primary match types: qualification and playoff. Qualification matches determine team rankings, with each team competing in multiple rounds to showcase their robot’s capabilities. Playoff matches involve alliances, where top-ranked teams form partnerships to compete in elimination rounds. These matches are high-stakes, requiring strategic teamwork and precise robot performance. The format ensures a balanced mix of individual skill and collaborative effort, culminating in the final rounds where the best teams vie for victory. Understanding these match types is crucial for teams to prepare effectively and maximize their chances of advancing through the tournament.

5.2 Alliance and Teamwork Dynamics

Alliances are a cornerstone of FTC competitions, fostering collaboration among teams; During playoffs, top-ranked teams form alliances, working together in elimination matches. Effective communication and strategic planning are essential, as teams must align their robot capabilities to maximize points. Trust and coordination are vital, ensuring seamless execution of game strategies. While alliances are temporary, they demand a deep understanding of each team’s strengths and weaknesses. This dynamic promotes not only competitive excellence but also camaraderie and mutual respect among participants. The success of an alliance often hinges on how well teams balance individual contributions with collective goals, making it a defining aspect of FTC events.

Awards and Judging Criteria

The FTC Game Manual outlines awards like the FIRST Tech Challenge Dean’s List and Winning Alliance, recognizing excellence in performance, innovation, and community impact.

6.1 Performance-Based Awards

Performance-based awards in FTC recognize teams excelling in specific areas during competitions. These include the Winning Alliance and Finalist Alliance awards, honoring top-performing teams. Additionally, the Control Award and Motivate Award celebrate technical prowess and community engagement. Teams are evaluated based on their robot’s performance, strategic gameplay, and overall contribution to the match outcomes. These awards incentivize innovation, teamwork, and effective execution, ensuring a competitive and dynamic environment for all participants.

6.2 Judging Criteria for Non-Performance Awards

Non-performance awards in FTC are judged based on specific criteria that emphasize innovation, design, and community impact. The Innovate Award recognizes creative solutions and unique robot designs, while the Design Award focuses on well-documented and efficient engineering. The Connect Award highlights teams’ efforts in community engagement and outreach, encouraging collaboration and spreading STEM awareness. Judges also evaluate the Think Award, which honors teams for their detailed engineering notebooks and strategic thinking. These awards celebrate holistic team efforts, rewarding not just technical skills but also creativity, documentation, and community involvement, fostering well-rounded development in participants. Sustainability and continuous outreach are key focuses.

Resources and Support

Official FTC resources and guides provide comprehensive support. Community forums, mentorship programs, and detailed manuals like the game manual and field tour ensure teams have ample tools to succeed.

7.1 Official FTC Resources and Guides

The FTC provides extensive resources to support teams, including the comprehensive game manual, field tour videos, and referee overviews. These official guides ensure clarity on rules and gameplay. Additional resources like curated lists for rookie teams and detailed explanations of mechanisms and components are available. The FTC website offers seasonal materials, including videos and challenge information, to help teams prepare. Regular updates and Q&A forums address common questions, while community forums and mentorship programs further enhance team support. These resources are essential for understanding the game and competing effectively.

7.2 Community and Mentorship Opportunities

The FTC fosters a strong community through forums, mentorship programs, and collaborative resources; Teams can engage with experienced mentors and peers to gain insights and improve their strategies. Online platforms and local workshops provide opportunities for knowledge sharing and skill development. Rookie teams benefit from curated guides and veteran advice, while experienced teams can contribute by mentoring others. These community-driven initiatives promote innovation, teamwork, and continuous learning, ensuring all participants have the support needed to excel in the competition.

Recent Updates and Changes

The 2024-2025 FTC season introduces “INTO THE DEEP,” with updates to game rules and sustainable outreach emphasis. The manual is released mid-July, detailing new challenges and guidelines.

8.1 Season-Specific Rule Changes

The 2024-2025 FTC season, titled “INTO THE DEEP,” introduces significant rule updates. The game manual, released mid-July, highlights changes in sustainable outreach valuation and continuous action requirements. Teams must adapt to new scoring mechanisms and field element interactions. Major updates include refined definitions of major mechanisms and penalties for improper component usage. The manual also clarifies rules on robot specifications and alliance dynamics during matches. These changes aim to enhance competition fairness and innovation, ensuring teams align with the season’s ocean-themed challenges. Staying updated is crucial for success in this dynamic competition environment.

8.2 Clarifications and Amendments

The FTC continuously refines the game manual to address ambiguities and incorporate feedback. Recent clarifications include updates on sustainable outreach criteria and continuous action requirements. The FTC also amended rules on major mechanisms, ensuring they align with game challenges. Additionally, the manual now explicitly outlines penalties for improper component usage and field interactions. These adjustments aim to maintain fairness and transparency. For instance, the FTC clarified that sustainable continuous outreach is prioritized over one-time events, reflecting its commitment to long-term impact. Teams are encouraged to regularly review updates to ensure compliance and optimal performance in the competition.

The FTC Game Manual serves as a roadmap for success, emphasizing understanding and adherence to rules. Continuous learning and improvement are key to thriving in the competition.

9.1 Final Tips for Success

To excel in FTC, thoroughly understand the Game Manual and stay updated on rule changes. Regularly test and refine your robot to ensure reliability. Foster strong teamwork and communication, as collaboration is key to success. Leverage resources like the Game Manual, official guides, and community support to address challenges. Stay adaptable and open to feedback, as continuous improvement is crucial. Encourage innovative thinking while adhering to competition rules. Finally, embrace the spirit of FIRST by promoting sportsmanship and gracious professionalism. By combining preparation, creativity, and perseverance, your team can achieve greatness in the FTC competition.

9.2 Encouragement for Continuous Learning

Continuous learning is vital for success in FTC. Encourage your team to regularly review the Game Manual and stay informed about updates. Participate in workshops, webinars, and community forums to gain insights and share knowledge. Embrace challenges as opportunities to grow and innovate. Collaborate with mentors and experienced teams to refine skills and strategies. Stay curious and open to new ideas, as the FTC competition evolves each season. By fostering a culture of lifelong learning, your team will not only excel in competitions but also develop valuable skills in robotics, engineering, and teamwork. Keep exploring, experimenting, and striving for excellence.